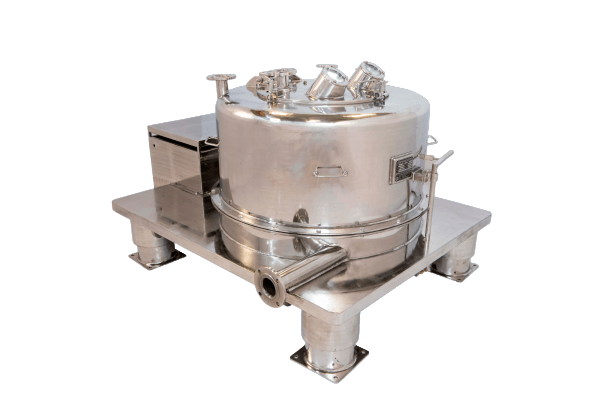

This is the most basic type of Centrifuge Machine that is widely used in many industries like Pharmaceutical, Chemical, R & D – Pilot Plant, Cosmetic, Food etc. Manual Top Discharge Centrifuge has a Vertical Basket assembly and is easy for processes having Easy to filter material characteristics. The slurry/ filterable material is loaded from the top and then the solids are removed Manually/ scooped from the Top of the machine These Machines are available in Four point suspension & 3 point Pendulum/ Suspension assembly.

Sturdy design & construction as per cGMP norms.

Four-point suspension type which requires negligible Foundation (Few bolts are to be grouted to prevent Lateral movement of Machine during operation)

The centrifuge is manufactured as per international standards with an inertia platform & AntiVibration mounts to Ensure smooth operation.

Vapour Tight Arrangement

Nitrogen purging system for Basket & bearing housing/ casing

Safety Devices such as Zero Speed Lock for the Centrifuge cover.

Full validation services are available including DQ, OQ, IQ, And Maintenance Manual.

cGMP construction for Pharmaceutical Models.

Kilolab Model to Production Models available